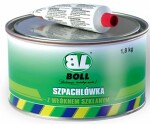

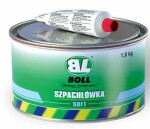

Fibreglass Putty 1,85kg+ hardener

2 component putties is manufactured on a base of polyester resins, which ensure head adhesion properties with different materials.

• is used as filling deep dents and corroded components korral.

• good mechanical duration and elasticity

• allows to cover high surfaces one at once leaving surface smooth easier aftertreatment .

Keskkonnasõbralikud täiteained.

Application areas:

automotive industry, machinerys construction etc

suitable for metal, for wood, for concrete, klaaskiule, reinforced plastics.

quality and Features:

work simplicity

big elasticity

very well hajutatav, as result on smooth surface

easy to grind also after pikemat perioodi

good stability even vertikaalsel surface

suitable for also zinc plated, Hot-dip galvanized or aluminium surfaces

durable nõrkadele against acids and alustele, fuels, for solvents, for water and jäätõrjesoolale

asbestos- and silicone-free

Technical Features:

stand: Polyester Resin mineral täiteainetega

paint: green

odor: stüreen

Serviceable life / operating time at temperature 20 ° C: approximately 4 minutes

Working temperature: min. 12 ° C

drying time (at temperature 20 ° C, 50% suhteline õhuniiskus): saab to grind u. 20-30 minutes

hardener addition: 2 - 4% (optimal mixture 2,5%)

temperature resistance

hardened material: 120 ° C

use:

before using read carefully etiketil olevaid hoiatavaid tekste and järgige neid!

Objektilt, what soovite improve tuleks to remove rust, surface black be clean, dry, rasvavaba and grinded.

take required pc pahtlit a purgist out and mix this well corresponding quantity hardener.

Apply mixed material desired layer thickness.

clean tools immediately after using, if necessary nitro-vedeldiga.

after u. 20–30 minutes saab repaired spaces to bore, to grind, saagida, raspeldada and to paint.

before paint layer mounting viimistlege middle teralisusega polüesterpahtliga (id 21661)

or Chamaeleon soft pahtliga Product ID: 21657.

Chamäleon

German manufacturer of high-quality putty products. the chameleon mark was first introduced in 1965 in schwerte.at that time chamäleon putty products were mainly produced for the German speaking market and represented the highest quality that professional users could count on. In 2002, it was decided to expand the range of putty products and start focusing on the international market. to realize this, the chamäleon brand was commissioned into a separate company under qualified management.

all putty products were still made in schwerte so that the company could move to foreign markets with excellent "made in germany" quality products. heidelberg, located in the rhine-neckar triangle, was chosen as the headquarters of the new company because of its infrastructure and ideal conditions for new expansion strategies.

chamäleon gmbh was able to successfully implement the set goals and was able to establish itself internationally with a wide range of car finishing products. the key to the success of the young company is to offer "made in Germany" quality products at very competitive prices and to offer the highest level of customer service. chamäleon gmbh works according to international quality standards, including the well-known iso 9001: 2015. the company received the strain thüringen certificate, which is proof of its continued commitment to quality and customer satisfaction.

Delivery method

The product delivery is not available to your selected destination.Car paint thickness gauge and car paint layers

A paint thickness gauge (or paint depth gauge) is used to measure the thickness of a vehicle's paint layer to determine whether the car has received a new paint coating after leaving the factory (either due to a previous accident, paint damage, etc.) or not. ). The repainted body part gives a higher reading than the part wearing the original paint.

... More...

A paint thickness gauge (or paint depth gauge) is used to measure the thickness of a vehicle's paint layer to determine whether the car has received a new paint coating after leaving the factory (either due to a previous accident, paint damage, etc.) or not. ). The repainted body part gives a higher reading than the part wearing the original paint.

... More...

Epoxy adhesives, epoxy resins and their use

Whether you are working with fiberglass, wood, cement, metal or plastic, epoxies are the perfect choice when you need an extra strong bond. Once you know how to choose the right epoxy resin, aka epoxy resin or epoxy glue (epoxy glue), for the material you're working with, you can confidently move forward with your project. This guide will help you understand how to use epoxy correctly so you can get the best results for your project.

... More...

Whether you are working with fiberglass, wood, cement, metal or plastic, epoxies are the perfect choice when you need an extra strong bond. Once you know how to choose the right epoxy resin, aka epoxy resin or epoxy glue (epoxy glue), for the material you're working with, you can confidently move forward with your project. This guide will help you understand how to use epoxy correctly so you can get the best results for your project.

... More...

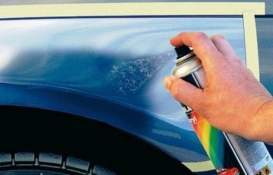

Putties and their use

Car body damage is very common. All it takes is a stone thrown from under the tire, careless parking, a minor collision or a scratch. Larger damages may require the help of a professional, but with smaller defects we can handle the corresponding putty ourselves.

... More...

Car body damage is very common. All it takes is a stone thrown from under the tire, careless parking, a minor collision or a scratch. Larger damages may require the help of a professional, but with smaller defects we can handle the corresponding putty ourselves.

... More...

RAL color chart

RAL is a European color matching system that defines the colors of paint, coatings, and plastics. The RAL color standard is maintained by the RAL Deutsches Institut für Gütesicherung und Kennzeichnung. “RAL” is an abbreviation for “Reichs-Ausschuß für Lieferbedingungen und Gütesicherung”.

... More...

RAL is a European color matching system that defines the colors of paint, coatings, and plastics. The RAL color standard is maintained by the RAL Deutsches Institut für Gütesicherung und Kennzeichnung. “RAL” is an abbreviation for “Reichs-Ausschuß für Lieferbedingungen und Gütesicherung”.

... More...

Information about painting and colors

General information and frequently asked questions about painting and spray paints. The article contains information about Motip-Duplicolor products, information about products from other brands may differ from the information provided here depending on the specifics of the product.

... More...

General information and frequently asked questions about painting and spray paints. The article contains information about Motip-Duplicolor products, information about products from other brands may differ from the information provided here depending on the specifics of the product.

... More...

The data shown here, especially the complete database of car spare parts, may not be copied. It is strictly prohibited to duplicate the data and database and distribute the same, and/or instruct third parties to engage in such activities, without prior consent from TecAlliance. Any use of content in a manner not expressly authorized constitutes copyright infringement and violators will be prosecuted.

The data shown here, especially the complete database of car spare parts, may not be copied. It is strictly prohibited to duplicate the data and database and distribute the same, and/or instruct third parties to engage in such activities, without prior consent from TecAlliance. Any use of content in a manner not expressly authorized constitutes copyright infringement and violators will be prosecuted.