putty epoxy 1kg

$31,20

Arrives in 3-4wd

ADD TO BASKET

epoxy putty

two-component epoxy putty for filling holes and leveling surfaces of concrete, wood, polyester and epoxy laminates. the correctly chosen viscosity of the mixture ensures easy application and perfect filling of cracks, voids and cavities. the hardened composition has excellent mechanical properties, resistance to water and aggressive environments, and easy processing. the product has high adhesion to various materials such as wood, steel, aluminum, polyester and epoxy laminates, except pe, pp, ptfe.

- the possibility of filling and molding the repair surfaces

- easy to process and paint

-impact resistant

- waterproof, resistant to weather conditions

application

materials: wood, wood-based materials, steel, aluminum, polyester laminates, epoxy laminates, concrete, brick, plaster, ceramics

application examples:

- leveling of epoxy-glass laminates

-repair of damage to laminates, e.g. repair of boats, caravans, kayaks

-strengthening and repairing garden figures, sculptures, etc.

-reinforcement and filling of concrete elements damaged by cold or mechanical forces

- filling damage of ceramic tiles

-repair of concrete elements, corners and surfaces of natural and synthetic stone

-priming of concrete elements, ensuring low absorption and good chemical resistance

technical parameters

color: gray

consistency: paste

shelf life after mixing: 10 min.

initial hardening: 1h

curing time for mechanical processing: 5-6 h

complete curing: 24 h

temperature tolerance: -30 0 c to 80 0 c

how to use

working conditions: use the glue at a temperature above 10 ° c.

surface preparation: glued surfaces black be clean, degreased and dry.

application:

1. apply resin and hardener to a flat surface, e.g. ceramic tile, in the following ratios:

-by weight: 100g resin, 50g hardener

-by volume: 100 ml of resin, 50 ml of hardener.

2. mix both ingredients thoroughly with a spatula.

3. apply the mixture to the repaired surface.

-make sure that spreading the mixture does not last longer than its use time, i.e. approx. 10 minutes.

-note the good saturation of the crack mixture at the damage site.

4. gradually fill larger gaps with 5-10 mm thick layers, leaving a gap of approx. 40 minutes between subsequent applications of the mass.

5. Leave the repaired element to fully cure.

- after about 5-6 hours, the repaired element can be sanded and painted with epoxy primer and varnish.

-full curing takes place after 24 hours (actual curing time may vary depending on

two-component epoxy putty for filling holes and leveling surfaces of concrete, wood, polyester and epoxy laminates. the correctly chosen viscosity of the mixture ensures easy application and perfect filling of cracks, voids and cavities. the hardened composition has excellent mechanical properties, resistance to water and aggressive environments, and easy processing. the product has high adhesion to various materials such as wood, steel, aluminum, polyester and epoxy laminates, except pe, pp, ptfe.

- the possibility of filling and molding the repair surfaces

- easy to process and paint

-impact resistant

- waterproof, resistant to weather conditions

application

materials: wood, wood-based materials, steel, aluminum, polyester laminates, epoxy laminates, concrete, brick, plaster, ceramics

application examples:

- leveling of epoxy-glass laminates

-repair of damage to laminates, e.g. repair of boats, caravans, kayaks

-strengthening and repairing garden figures, sculptures, etc.

-reinforcement and filling of concrete elements damaged by cold or mechanical forces

- filling damage of ceramic tiles

-repair of concrete elements, corners and surfaces of natural and synthetic stone

-priming of concrete elements, ensuring low absorption and good chemical resistance

technical parameters

color: gray

consistency: paste

shelf life after mixing: 10 min.

initial hardening: 1h

curing time for mechanical processing: 5-6 h

complete curing: 24 h

temperature tolerance: -30 0 c to 80 0 c

how to use

working conditions: use the glue at a temperature above 10 ° c.

surface preparation: glued surfaces black be clean, degreased and dry.

application:

1. apply resin and hardener to a flat surface, e.g. ceramic tile, in the following ratios:

-by weight: 100g resin, 50g hardener

-by volume: 100 ml of resin, 50 ml of hardener.

2. mix both ingredients thoroughly with a spatula.

3. apply the mixture to the repaired surface.

-make sure that spreading the mixture does not last longer than its use time, i.e. approx. 10 minutes.

-note the good saturation of the crack mixture at the damage site.

4. gradually fill larger gaps with 5-10 mm thick layers, leaving a gap of approx. 40 minutes between subsequent applications of the mass.

5. Leave the repaired element to fully cure.

- after about 5-6 hours, the repaired element can be sanded and painted with epoxy primer and varnish.

-full curing takes place after 24 hours (actual curing time may vary depending on

Technicqll

technicqll is a polish company that has specialized in the production of high-quality adhesives, sealants and chemical preparations since 1985. Their product range includes epoxy, cyanoacrylate and solvent-based adhesives, silicones, sealants, lubricants and cleaning and maintenance products, designed for both home use and professional applications. technicqll products are known for their reliability and durability, providing solutions for joining and repairing various materials, such as metal, wood, plastic, ceramics and glass. The company's goal is to provide its customers with a "technical first aid kit" that will help them quickly and efficiently solve various repair and maintenance tasks.

Delivery method

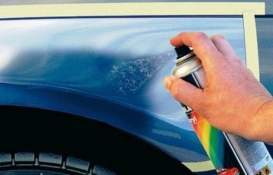

The product delivery is not available to your selected destination.Car paint thickness gauge and car paint layers

A paint thickness gauge (or paint depth gauge) is used to measure the thickness of a vehicle's paint layer to determine whether the car has received a new paint coating after leaving the factory (either due to a previous accident, paint damage, etc.) or not. ). The repainted body part gives a higher reading than the part wearing the original paint.

... More...

A paint thickness gauge (or paint depth gauge) is used to measure the thickness of a vehicle's paint layer to determine whether the car has received a new paint coating after leaving the factory (either due to a previous accident, paint damage, etc.) or not. ). The repainted body part gives a higher reading than the part wearing the original paint.

... More...

Epoxy adhesives, epoxy resins and their use

Whether you are working with fiberglass, wood, cement, metal or plastic, epoxies are the perfect choice when you need an extra strong bond. Once you know how to choose the right epoxy resin, aka epoxy resin or epoxy glue (epoxy glue), for the material you're working with, you can confidently move forward with your project. This guide will help you understand how to use epoxy correctly so you can get the best results for your project.

... More...

Whether you are working with fiberglass, wood, cement, metal or plastic, epoxies are the perfect choice when you need an extra strong bond. Once you know how to choose the right epoxy resin, aka epoxy resin or epoxy glue (epoxy glue), for the material you're working with, you can confidently move forward with your project. This guide will help you understand how to use epoxy correctly so you can get the best results for your project.

... More...

Putties and their use

Car body damage is very common. All it takes is a stone thrown from under the tire, careless parking, a minor collision or a scratch. Larger damages may require the help of a professional, but with smaller defects we can handle the corresponding putty ourselves.

... More...

Car body damage is very common. All it takes is a stone thrown from under the tire, careless parking, a minor collision or a scratch. Larger damages may require the help of a professional, but with smaller defects we can handle the corresponding putty ourselves.

... More...

RAL color chart

RAL is a European color matching system that defines the colors of paint, coatings, and plastics. The RAL color standard is maintained by the RAL Deutsches Institut für Gütesicherung und Kennzeichnung. “RAL” is an abbreviation for “Reichs-Ausschuß für Lieferbedingungen und Gütesicherung”.

... More...

RAL is a European color matching system that defines the colors of paint, coatings, and plastics. The RAL color standard is maintained by the RAL Deutsches Institut für Gütesicherung und Kennzeichnung. “RAL” is an abbreviation for “Reichs-Ausschuß für Lieferbedingungen und Gütesicherung”.

... More...

Information about painting and colors

General information and frequently asked questions about painting and spray paints. The article contains information about Motip-Duplicolor products, information about products from other brands may differ from the information provided here depending on the specifics of the product.

... More...

General information and frequently asked questions about painting and spray paints. The article contains information about Motip-Duplicolor products, information about products from other brands may differ from the information provided here depending on the specifics of the product.

... More...

The data shown here, especially the complete database of car spare parts, may not be copied. It is strictly prohibited to duplicate the data and database and distribute the same, and/or instruct third parties to engage in such activities, without prior consent from TecAlliance. Any use of content in a manner not expressly authorized constitutes copyright infringement and violators will be prosecuted.

The data shown here, especially the complete database of car spare parts, may not be copied. It is strictly prohibited to duplicate the data and database and distribute the same, and/or instruct third parties to engage in such activities, without prior consent from TecAlliance. Any use of content in a manner not expressly authorized constitutes copyright infringement and violators will be prosecuted.